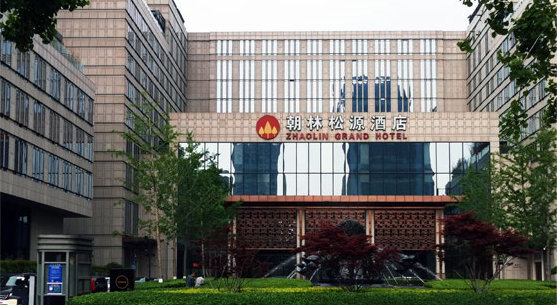

Two Zhaolin Plaza office buildings in Beijing's core business district installed Vulcan S500 units on their central air-conditioning circulating water systems. After 5 months, chemical inhibitors were completely replaced, scale fell off cooling tower packing, and the system operated stably with conductivity up to 6630 µS/cm—significantly reducing wastewater discharge.

A 1,000 room resort located on the beachfront in Punta Cana, Dominican Republic. Two Vulcan S500 were installed on the main input pipe in order to combat scale build up and increase efficiency of the three cooling towers. A Vulcan S100 is also installed on the resorts main hot water system, in order to remove and prevent scale build up in the heaters/boilers, which provide hot water throughout the entire resort and casino.

Before the Vulcan ant-scale solution was installed the factory pipelines were often blocked. This in increased the pressure in the pipe and even made the pipe explode. In the past, the company used salt-based softener to solve the scaling problems, but the result was not satisfactory. 3 Months after installing the Vulcan solution the factory pipes and equipments are still running well without getting blocked.

Before Vulcan S100 was installed in hotel’s main hot water line, the storage tanks had a solid 3 cm thick scale layer inside them and the pumping pressure from the booster set was at maximum while being unable to deliver adequate water pressure to the end of the line hotel rooms.

A 4 year field test of the Vulcan electronic descaler was conducted at a Mall’s cooling towers in Indonesia. During the 4 years no system maintenance was required and the system was not treated with chemicals. Mall administration and maintenance report the prevention of rust in their iron pipes has been an added benefit.

This installation was a government project and before the Vulcan descalers were installed it took a great deal of effort and expense to clean the heat exchangers. The Vulcan system has already proven its effectiveness since it has greatly prolonged the cleaning intervals. This government contract has reported they are very satisfied with the results of the Vulkcan descalers being able to effectively solve mineral scaling problems of the heat exchangers.

Page 2 of 3

The Vulcan mineral descaling hard water softening technology has been installed with success across the world: