The March 31, 2026 Deadline

Buildings over 50,000 square feet on the 10-year audit cycle face a firm deadline: March 31, 2026 for the 2025 cycle LL87 Energy Audit and Retro-Commissioning report.

March 31

2026 deadline

LL87 audit due

50k+

Square feet

Buildings required to file

10 Year

Audit cycle

Retro-commissioning required

Most building owners treat this as a paperwork exercise. The auditor walks the building, checks a few boxes, files the report, and everyone moves on.

In 2026, that changes. The 2025-2026 audit cycle is the first to occur after LL97 penalties went into effect. Auditors are now trained to look for root causes of inefficiency, not just symptoms.

The New Reality

Auditors are now cross-referencing LL87 findings with LL84 benchmarking data and LL97 emissions reports. If your audit shows deferred maintenance, the DOB will assume your emissions reports are inaccurate.

What Auditors Actually Measure

Boiler Stack Temperature

High stack temperature = scale insulation = heat going up chimney instead of into water.

Heat Exchanger Delta-T

Low delta-T = fouled heat transfer surfaces = scale buildup reducing efficiency.

Hot Water Return Temp

Cold return = heat loss in pipes = internal scale or insulation failure.

Critical Measurements

| Measurement | What's Normal | What Flags an Issue |

|---|---|---|

| Boiler stack temp | Design spec ± 25°F | >100°F above design = scale insulation |

| Heat exchanger delta-T | Design spec (often 20°F) | <80% of design = fouling |

| Hot water return | 110-120°F | <110°F = heat loss in pipes |

What Auditors Recommend (and What It Costs)

When They Find Scale

- Heat exchanger fouled: "Replace heat exchanger" - $15,000 to $50,000

- Boiler short-cycling: "Replace boiler" - $150,000 to $500,000

- Recirculation loss: "Replace risers" - $500,000 to $2,000,000

Better Alternative

- Descale in place: Restore efficiency without replacement

- Document improvement: Show auditor verified efficiency gain

- Extend equipment life: 5-7 more years from existing systems

The auditor's verdict: "Verified efficiency improvement. No replacement required."

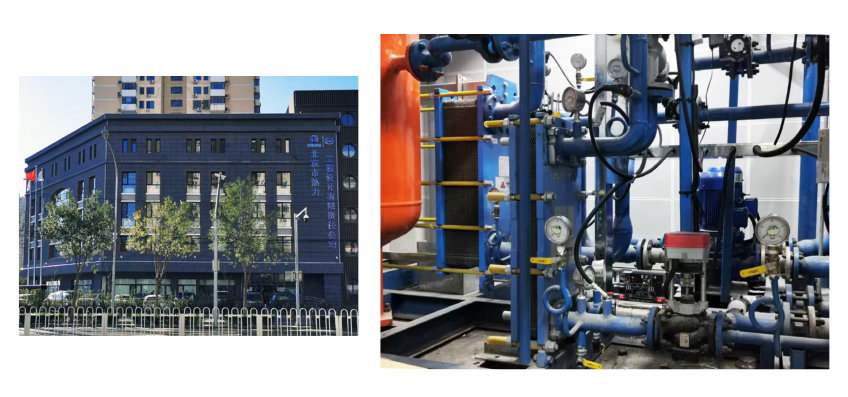

Real Proof: Beijing Thermal Engineering Protects Plate Heat Exchangers

Company: Beijing Thermal Engineering Company

Application: Plate heat exchangers in hot water systems

The Challenge

Plate heat exchangers are particularly vulnerable to scale because of their narrow passages and high heat transfer rates. Beijing Thermal Engineering was using chemical scale inhibition products, but wanted a non-chemical solution that required no ongoing maintenance.

The Solution

Vulcan was installed to replace chemical scale inhibition products. The goal: prevent plate heat exchanger scaling in hot water systems without chemicals, salt, or ongoing maintenance. For this application, the Vulcan S25 or S50 provided the right capacity.

The Results

- Chemical scale inhibition eliminated

- Plate heat exchangers protected from scaling

- Delta-T maintained at design specifications

- No ongoing maintenance or chemical handling

Why This Matters for Your LL87 Audit: When the auditor measures delta-T on your heat exchangers, they'll see numbers at design spec. No flags, no replacement recommendations, just a check mark in the "properly maintained" column.

How Vulcan Prepares You for the LL87 Audit

Restored Delta-T

Heat exchangers return to manufacturer-specified temperature differential. Auditors see "properly maintained."

Normal Stack Temperatures

Boilers operate at design efficiency. No flags for scale insulation.

Proper Hot Water Return

Clean pipes mean heat stays in the water, not lost to scale insulation.

Audit-Ready Documentation

Installation dates, pre/post measurements, and verified improvements ready to show.

The Auditor's Verdict

"Verified efficiency improvement. No replacement required. Equipment properly maintained."

The 60-Day Window

You have approximately 60 days before the March 31 LL87 deadline to perform internal inspections and install remediation equipment.

Immediate

Pull your 2015 LL87 audit. Compare equipment conditions then vs. now.

Week 1-2

Measure hot water return temps. Below 110°F = problem.

Week 2-3

Boroscope boiler tubes. Buildup thicker than a credit card = money lost.

Week 3-4

Install Vulcan, document baseline, measure improvement before audit.

Don't wait for the auditor to find what you could have fixed.

The ROI of Passing Your Audit

| Heat exchanger replacement (flagged in audit) | $15,000 - $50,000 |

| Boiler replacement (flagged in audit) | $150,000 - $500,000 |

| DOB violations and permit delays | $10,000+ |

| Vulcan model (typical installation) | Login for pricing |

| Audit outcome with Vulcan | "Verified. No replacement needed." |

Get Exact Pricing for Your Building

For precise pricing tailored to your building's specifications:

- Existing customers: Log in to your account to view model-specific pricing

- New users: Create a free account to access detailed pricing and configuration options

- Need assistance? Contact our team for a pre-audit assessment

Account registration takes less than 2 minutes.

* Savings vary based on building size, equipment condition, and audit findings.

Selecting the Right Model for Your Building

Different building sizes require different Vulcan models. Create an account to view detailed specifications and pricing.

| Building Size | Typical Equipment | Recommended Model | Pipe Size | Flow Rate |

|---|---|---|---|---|

| 50k-100k sq ft | Boilers, heat exchangers, DHW | Vulcan S10 or S25 | 3-4" | 65-130 GPM |

| 100k-250k sq ft | Multiple boilers, central plant | Vulcan S50 or S100 | 5-6" | 300-530 GPM |

| 250k-500k+ sq ft | Large central plants, district systems | Vulcan S150 or larger | 8-40" | 790+ GPM |

Pre-Audit Checklist

- Pull your 2015 LL87 audit and compare equipment conditions

- Measure hot water return temperatures at the farthest point

- Boroscope boiler tubes to check for scale buildup

- Measure heat exchanger delta-T on all critical systems

- Document any efficiency deficiencies with photos and data

- Install Vulcan to address scale issues before the audit

- Measure and document post-installation improvements

- Prepare your Good Faith file with all documentation

Questions Your Auditor Will Ask

- "When was the last time you cleaned your heat exchangers?"

- "What is your current boiler efficiency compared to nameplate?"

- "Why is your delta-T measuring 12°F when design is 20°F?"

- "What maintenance have you performed on the hot water system?"

- "Can you show me records of scale prevention measures?"

- "Have you noticed any change in hot water delivery times?"

With Vulcan documentation, you have answers ready.

Pass Your LL87 Audit

March 31 is coming fast. Don't let scale force expensive replacements.

About the Author

Waslix provides non-chemical, maintenance-free scale prevention using Vulcan technology. We help building owners pass LL87 audits by keeping heat exchangers, boilers, and pipes operating at design efficiency. Create an account for detailed model specifications and pricing.