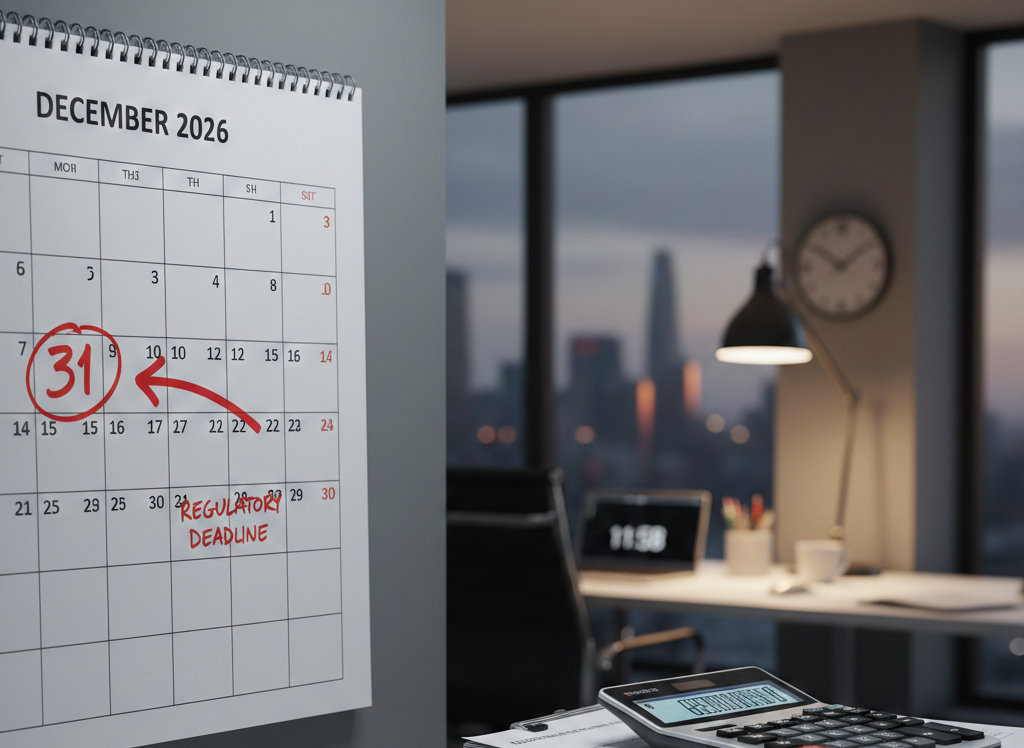

December 31, 2026: The Deadline You Can't Miss

On December 1, 2025, NYSDEC issued final regulations for the Mandatory Greenhouse Gas Reporting Program. Large emission sources have less than 10 months to comply.

10

Months remaining

until deadline

>25k

MT CO2e threshold

Facilities required to file

$37.5k

Per day penalty

For missing requirements

Who must file: Any facility emitting more than 25,000 metric tons of CO2 equivalent per year must submit a written greenhouse gas monitoring plan to NYSDEC by December 31, 2026.

"Each failure to measure or collect information that is required by the regulations is a separate violation."

The Trap

Each metric ton misreported is a separate violation. A single error can trigger $500,000+ in fines and potential criminal liability for false statements.

What Your Monitoring Plan Must Include

Personnel

Identification of personnel responsible for data collection

Methods

Methods used to collect required data

Maintenance

Methods for quality assurance, maintenance, and repair of all measuring devices

Your heat exchanger is a measuring device. It measures temperature differential (delta-T), which is essential for calculating heat transfer efficiency and, ultimately, emissions.

Questions Your Plan Must Answer

- How do you ensure your heat exchanger delta-T measurements are accurate?

- What maintenance do you perform to keep heat transfer surfaces clean?

- How do you verify that reported efficiency reflects actual performance?

- What is your quality assurance method for heat transfer measurements?

Why Your Heat Exchanger Is a "Measuring Device"

NYSDEC regulations require your monitoring plan to include methods for quality assurance, maintenance, and repair of all measuring devices. Here's why heat exchangers qualify:

Temperature Differential

Delta-T between inlet and outlet is a critical measurement for efficiency and emissions calculations.

Flow Rate

Flow measurements depend on clean pipes. Scale reduces diameter and affects accuracy.

Pressure Drop

Pressure measurements indicate fouling. Clean surfaces mean accurate readings.

The Critical Point

If your heat exchanger is fouled with mineral scale, your measurements are wrong. You are reporting emissions based on assumed efficiency, not actual efficiency. That is a violation of your monitoring plan.

Real Proof: BD Rapid Diagnostics Protects High-Temperature Systems

Company: BD Rapid Diagnostics (Becton Dickinson)

Industry: Healthcare safety and technologies

The Challenge

BD's steam room operates at high temperatures (more than 80°C). High-temperature systems are particularly vulnerable to rapid, aggressive scale formation. Scale was affecting their hot water system and threatening critical healthcare manufacturing processes.

The Solution

BD installed Vulcan mineral descalers to solve the scaling problems in their high-temperature hot water system. For industrial healthcare applications, the Vulcan S25 or S50 provide the necessary capacity.

The Results

- High-temperature steam room protected from scale

- Accurate temperature measurements maintained

- No chemicals, no salt, no ongoing maintenance

- Documented quality assurance for critical measurements

Why This Matters for Your Monitoring Plan: BD can now document in their monitoring plan that they have a quality assurance method for their high-temperature heat transfer surfaces. When regulators ask "How do you ensure your measurements are accurate?", BD has proof.

How Vulcan Strengthens Your Monitoring Plan

Quality Assurance Method

Vulcan provides a documented method for maintaining heat transfer surface cleanliness, directly addressing the maintenance requirement.

Measurement Accuracy

Clean heat exchangers mean delta-T measurements reflect actual performance, not fouled conditions.

Maintenance Documentation

Installation date, pre/post measurements, and long-term records provide audit-ready proof.

No Ongoing Requirements

Unlike chemical treatment, Vulcan requires no ongoing verification or reporting, simplifying your plan.

Sample Monitoring Plan Language

"Quality Assurance for Heat Transfer Surfaces: The facility has installed permanent, non-chemical scale prevention technology (Vulcan) on all critical heat exchangers. Installation date: [DATE]. Pre-installation delta-T measurements: [DATA]. Post-installation measurements show sustained design efficiency. No additional maintenance required."

The Cost of Missing Requirements

$37,500/day

Civil penalty per violation

Per MT

Each misreported ton = separate violation

$500k+

Potential criminal fines

| Missing personnel requirement | $37,500/day |

| Missing collection methods | $37,500/day |

| Missing quality assurance methods | $37,500/day |

| Missing maintenance methods | $37,500/day |

| Total daily exposure (4 missing elements) | $150,000/day |

Get Exact Pricing for Your Facility

For precise pricing tailored to your facility's specifications:

- Existing customers: Log in to your account to view model-specific pricing

- New users: Create a free account to access detailed pricing and configuration options

- Need assistance? Contact our team for a monitoring plan consultation

Account registration takes less than 2 minutes.

Selecting the Right Model for Your Facility

Different facilities require different Vulcan models. Create an account to view detailed specifications and pricing.

| Facility Type | Typical Application | Recommended Model | Pipe Size | Flow Rate |

|---|---|---|---|---|

| Small industrial / lab | Steam generators, small heat exchangers | Vulcan S10 | Up to 3" | 65 GPM |

| Mid-size industrial / healthcare | Boilers, steam systems, process heat exchangers | Vulcan S25 or S50 | 4-5" | 130-300 GPM |

| Large industrial / campus | Central plants, district heating, large process systems | Vulcan S100 or S150 | 6-8" | 530-790 GPM |

| Very large industrial / power | Large cooling towers, extensive process systems | Vulcan S250 or larger | 10-40" | 1,540+ GPM |

The 10-Month Countdown

Month 1-2

Identify all measuring devices including heat exchangers

Month 3-4

Assess current maintenance methods and gaps

Month 5-6

Install Vulcan, document baseline measurements

Month 7-10

Draft and submit monitoring plan by Dec 31

Don't wait until December. Build your monitoring plan now.

NYSDEC Monitoring Plan Requirements

- Personnel identification – Who is responsible for data collection?

- Data collection methods – How will you measure required parameters?

- Quality assurance methods – How do you ensure data accuracy? (Vulcan provides this for heat exchangers)

- Maintenance methods – How do you maintain measuring devices? (Vulcan requires no maintenance)

- Repair procedures – What happens when devices fail?

- Documentation – How will you record and store data?

- Need assistance? Contact our team for help integrating Vulcan into your monitoring plan.

Don't Miss the December 31 Deadline

Your monitoring plan needs a quality assurance method for heat transfer surfaces. Vulcan provides it.

About the Author

Waslix provides non-chemical, maintenance-free scale prevention using Vulcan technology. We help facilities meet NYSDEC monitoring plan requirements by providing documented quality assurance for heat transfer surfaces. Create an account for detailed model specifications and pricing.